PET Bottle Flake Granulation Line

PET Bottle Recycling Pelletizer PET Granulation Machine Process eruba

Nkọwa nka nka

|

Aha igwe |

PET Single ịghasa Extrusion pelletizing Line |

|

Akụrụngwa |

rPET flakes |

|

Ngwaahịa ikpeazụ |

rPET mpempe akwụkwọ |

|

Ngwa Line Production | Sistemụ nkụ kristal infrared: Vacuum feeder/Infrared crystal dryer/Vacuum discharger

Single Screw Extrusion granulating line: Otu ịghasa isi extruder/Hydraulic Double Pistons onye na-agbanwe ihuenyo / isi anwụ anwụ / igwe na-agba mmiri / na-efesa pellitizer / igwe na-ekpo ọkụ kwụ ọtọ / igwe siri ike na-ama jijiji / nchekwa

|

|

dayameta ịghasa |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Oke mmepụta |

150-1000KG/H |

|

Ihe kpochie |

38CrMoAlA nwere ọgwụgwọ Nitrding |

|

Ụdị Pelletizing |

Mkpọsa mmiri na pelletizing |

|

Ihe ngbanwe ihuenyo |

Hydraulic Mgbanwe ihuenyo Pistons ugboro abụọ |

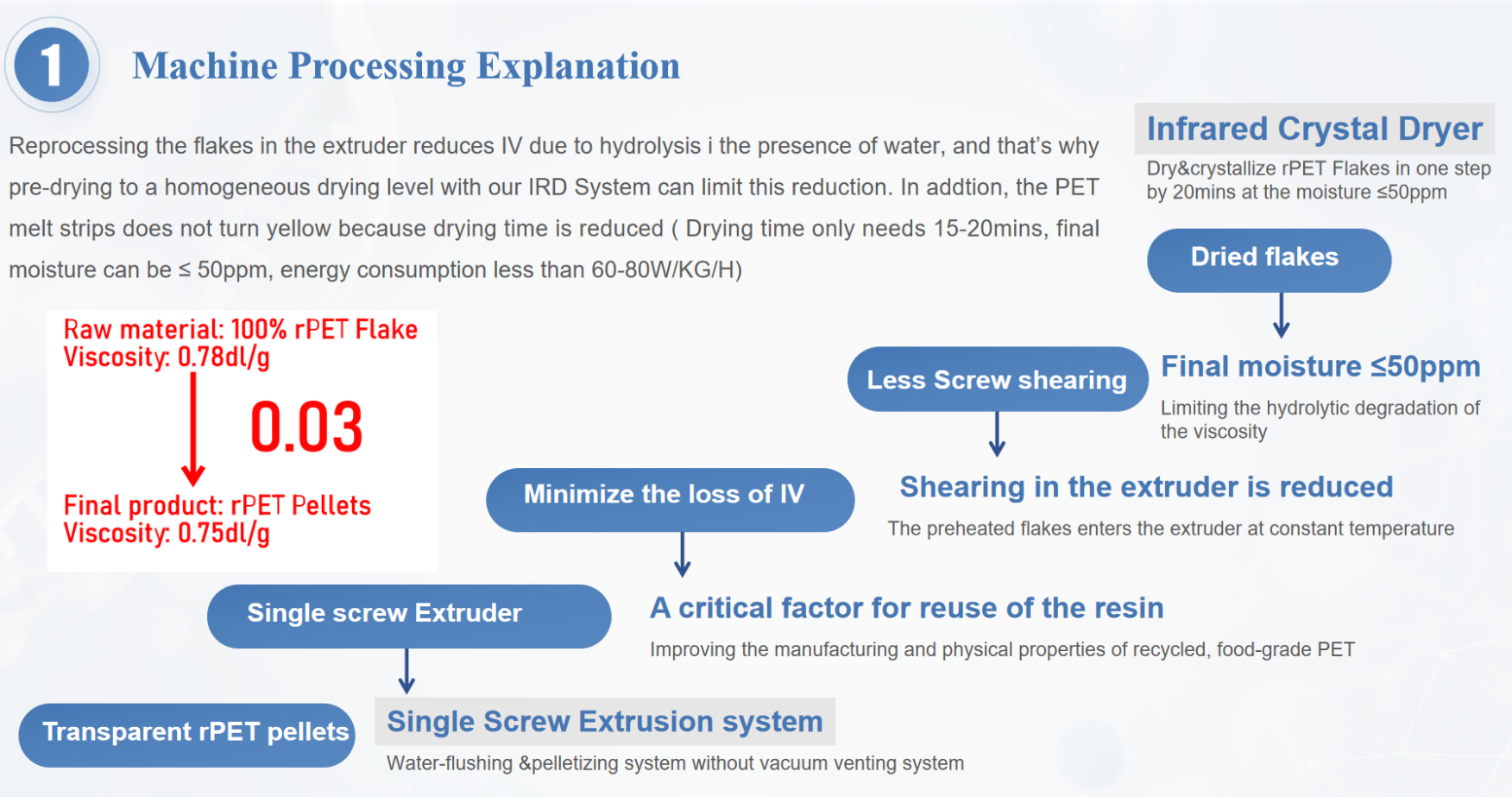

Nkọwa igwe

Igwe mmiri infrared kristal (LIANDA PATENT DESIGN)

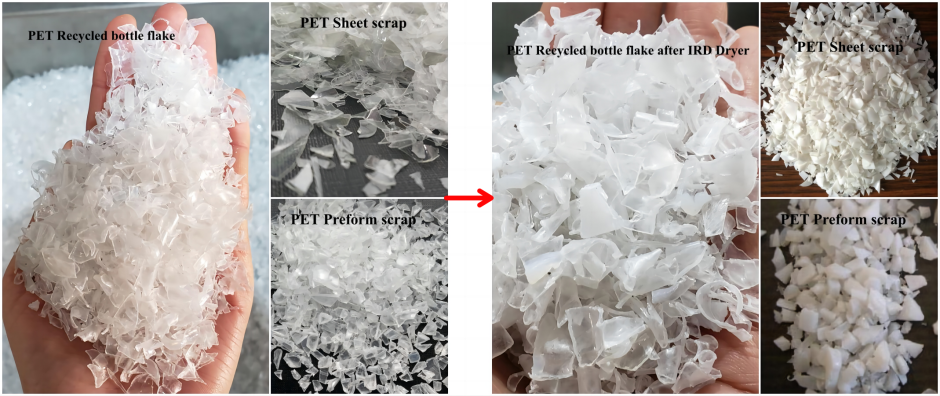

① Ịkwalite mmepụta na akụrụngwa anụ ahụ nke emegharịrị, ọkwa nri PET site na teknụzụ nke infrared na-akwado nwere akụkụ dị mkpa iji rụọ ọrụ na viscosity intrinsic (IV).

②Ebu crystallization & ihicha flakes tupu extrusion na-enyere aka belata mfu nke IV site na PET, ihe dị mkpa maka iji resin ọzọ.

③ Ịmegharị flakes na extruder na-ebelata IV n'ihi hydrolysis n'ihu mmiri, ọ bụ ya mere tupu ihicha ya na ọkwa ihicha nke ọma na usoro IRD anyị nwere ike igbochi mbelata a.

Na mgbakwunye, ibe agbaze PET anaghị atụgharị edo edo n'ihi na oge ihicha na-ebelata (oge ịsa mmiri chọrọ naanị 15-20mins, mmiri ikpeazụ nwere ike ịbụ ≤ 30ppm, oriri ike na-erughị 60-80W / KG / H)

④ A na-esikwa otú a na-akpụzi ịkwa ákwà na extruder n'ihi na ihe ndị a na-ekpo ọkụ na-abanye na extruder na okpomọkụ mgbe niile"

⑤Mmelite mmepụta nke PET Extruder

Enwere ike nweta mmụba nke nnukwu njupụta site na 10 ruo 20% na IRD, na-eme ka arụmọrụ nri dị na ntinye ntinye nke extruder nke ukwuu - ebe ọsọ extruder na-agbanwe agbanwe, enwere arụmọrụ njuputa nke ọma na ịghasa.

Line Pelletizing Single Screw Extrusion Extrusion (Na-enweghị Vacuum Venting)

N'iji ike nke Single screw extruder na ijikọta ya na LIANDA nke a haziri nke ọma maka flakes rPET, anyị nwere ike ịbawanye ikike site na 20% na obere ike riri ma e jiri ya tụnyere Parallel double screw extruder.

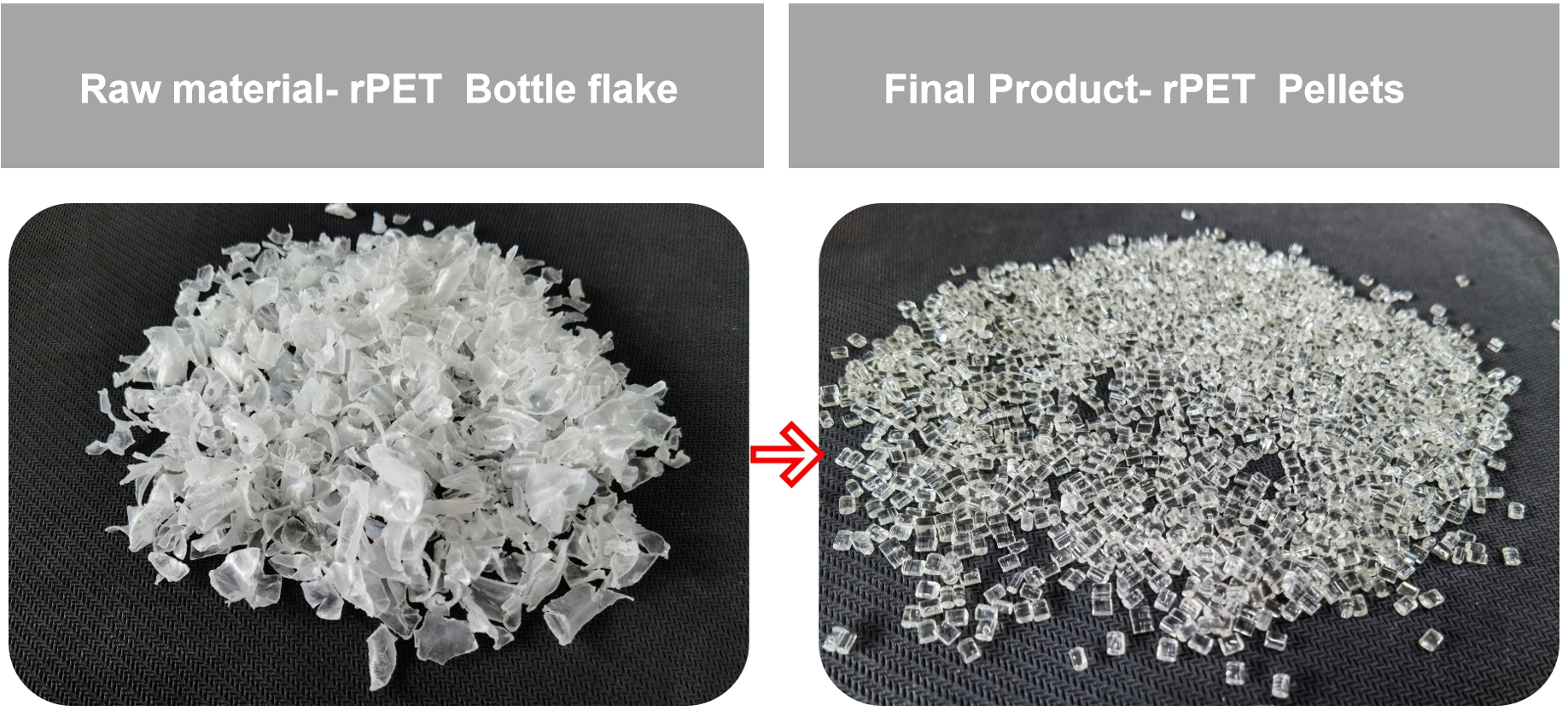

Viscosity nke pellet rPET nke sistemu anyị mepụtara: enwere naanị ≤0.02-0.03dl/g viscosity drop ---na-agbakwunyeghị ihe nkwalite viscosity ọ bụla. (Dịka nnwale ụlọ anyị siri dị)

rPET pellets Agba: nghọta --- na-agbakwunyeghị ihe nkwalite nghọta ọ bụla

Na-enweghị sistemụ ikuku ikuku --- Ịchekwa ọnụ ahịa ike, enweghị nsogbu yana ịrụ ọrụ kwụsiri ike

Foto igwe