PET Granulating ahịrị

Infrared Crystallization Dryer maka ahịrị rPET Extrusion granulating

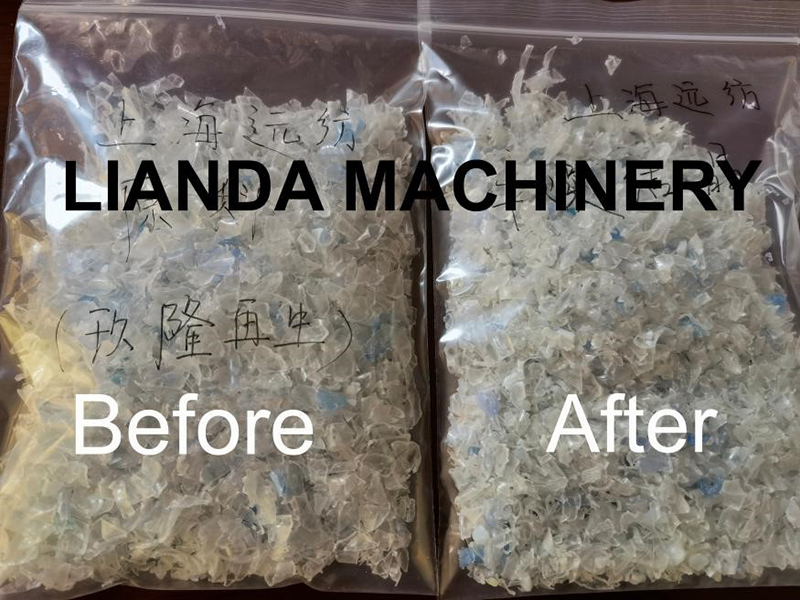

Infrared Pre-ihicha nke rPET Bottle Flakes: Mmepụta na-abawanye na ịkwalite ogo na PET Extruders.

Ịkpọ nkụ bụ otu mgbanwe kachasị mkpa na nhazi.

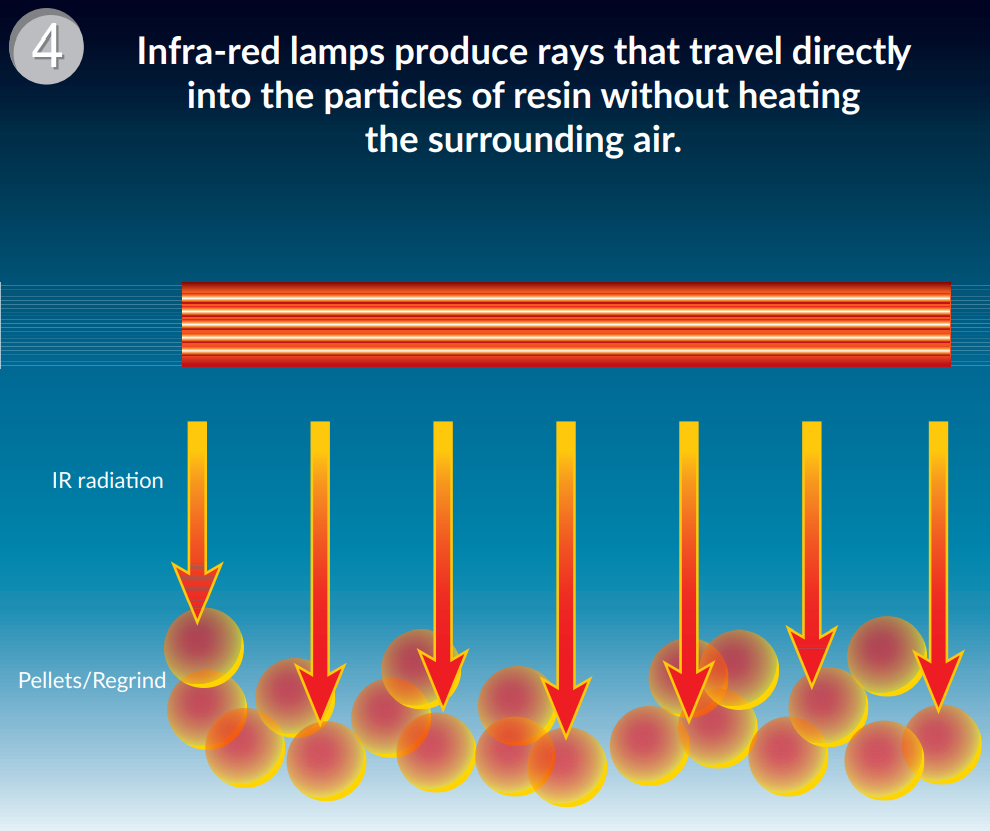

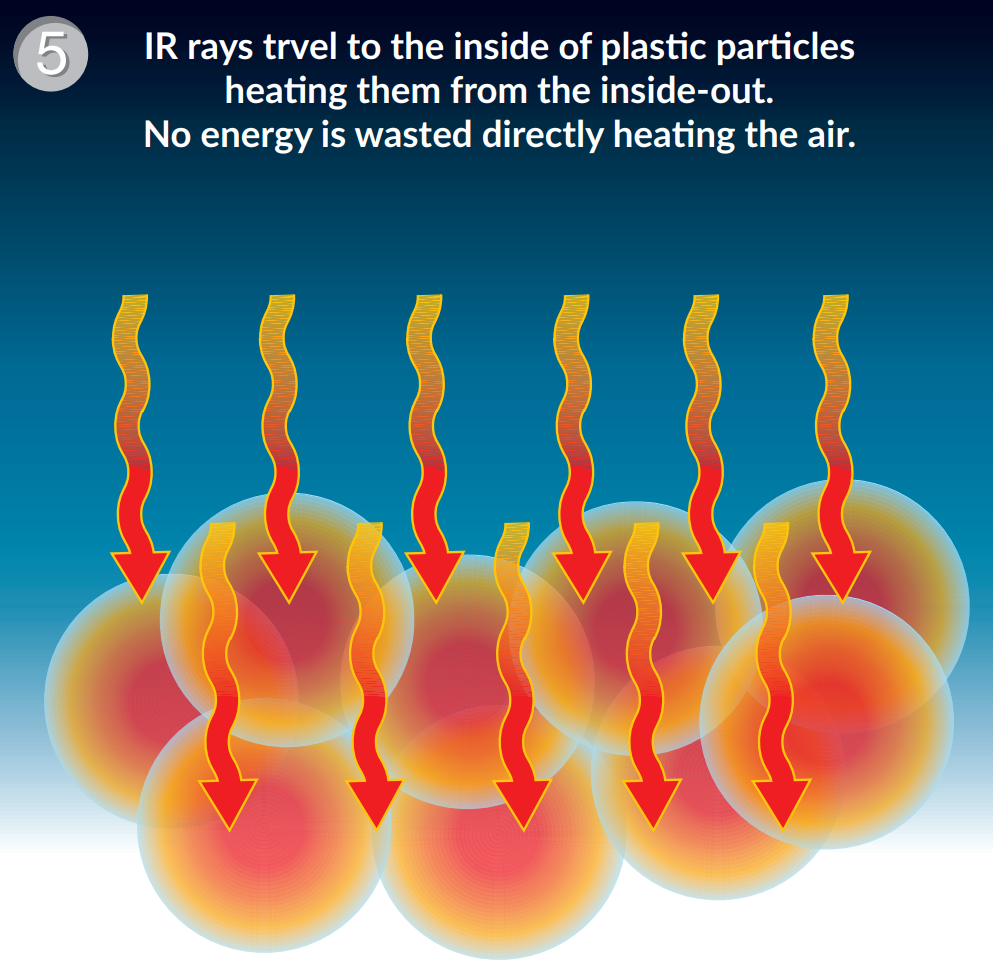

>> Imeziwanye nrụpụta na akụrụngwa anụ ahụ nke emegharịrị, ọkwa nri PET site na teknụzụ nke ọkụ infrared kwadoro nwere akụkụ dị mkpa iji rụọ ọrụ na viscosity intrinsic (IV).

>> pre-crystallization & ihicha flakes tupu extrusion na-enyere aka belata mfu nke IV site na PET, ihe dị mkpa maka iji resin mee ihe.

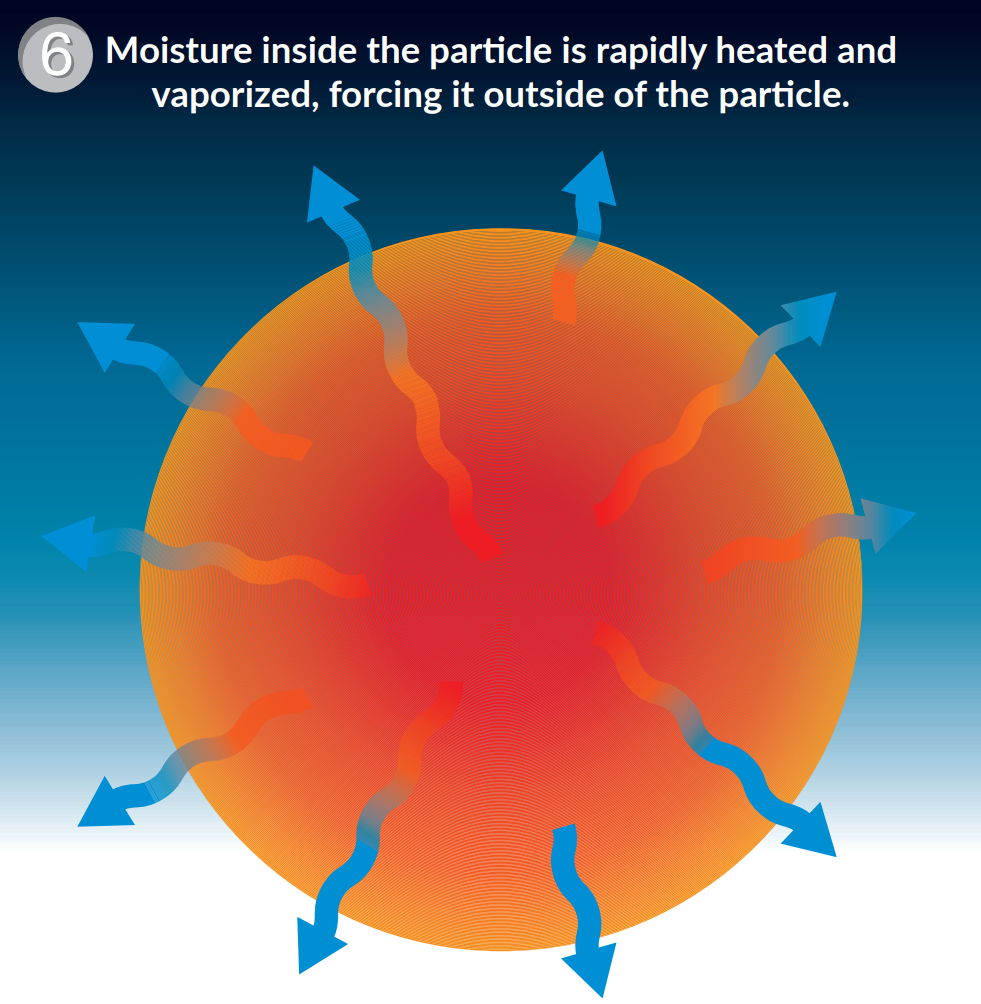

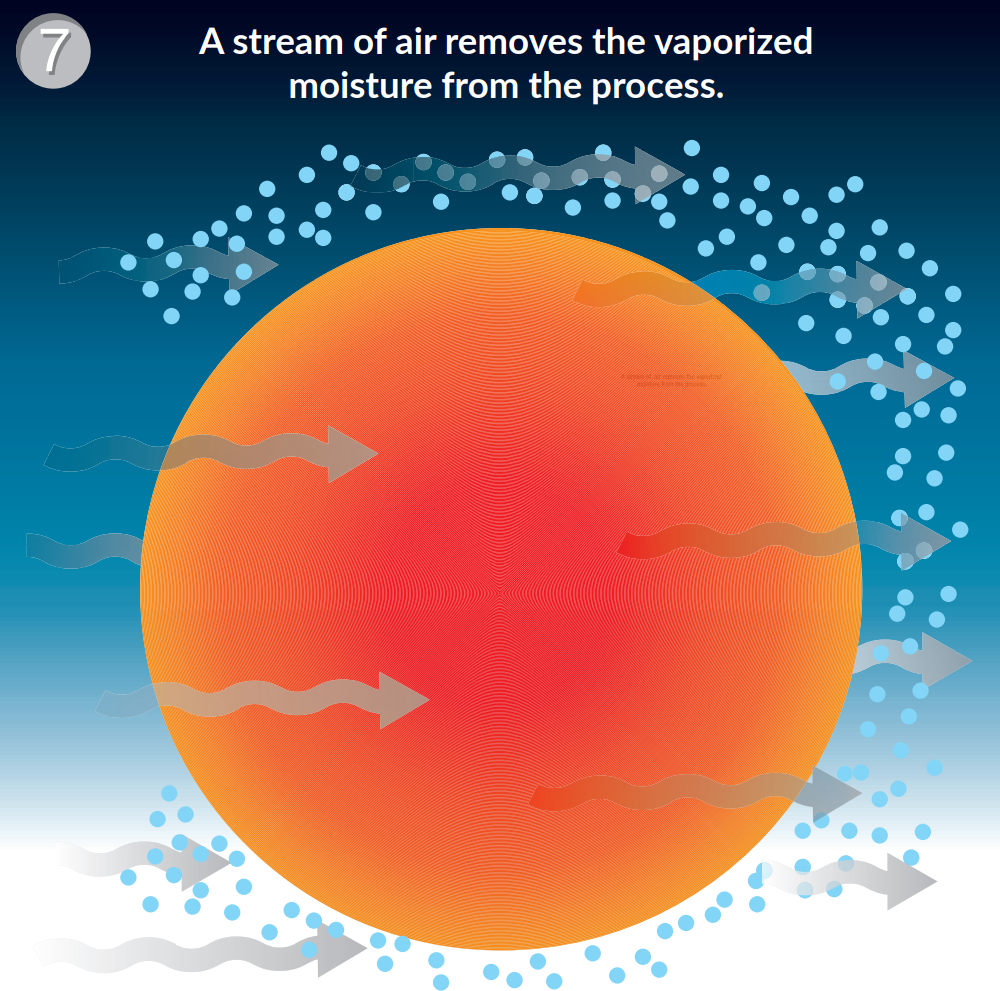

>> Reprocessing na flakes na extruder ebelata IV n'ihi hydrolysis m ọnụnọ nke mmiri, na nke ahụ bụ ihe mere tupu ihicha ka a homogeneous ihicha larịị na anyị IRD System nwere ike amachi a Mbelata. Na mgbakwunye,Ebe mgbaze PET anaghị atụgharị edo edo n'ihi na oge ihicha na-ebelata(Oge ihicha naanị chọrọ 15-20mins, mmiri ikpeazụ nwere ike ịbụ ≤ 30ppm, ike oriri na-erughị 80W/KG/H)

>> A na-esikwa otú ahụ belata n'ịkpụcha ihe na extruder n'ihi na ihe a na-ekpo ọkụ na-abanye na extruder na okpomọkụ mgbe niile"

>> Imelite mmepụta PET Extruder

Enwere ike nweta mmụba nke nnukwu njupụta site na 10 ruo 20% na IRD, na-eme ka arụmọrụ nri dị na ntinye ntinye nke extruder nke ukwuu - ebe ọsọ extruder na-agbanwe agbanwe, enwere arụmọrụ njuputa nke ọma na ịghasa.

Ụkpụrụ ọrụ

Uru anyị na-eme

※Na-egbochi mmebi hydrolytic nke viscosity.

※ Gbochie ịba ụba ọkwa AA maka akụrụngwa nwere kọntaktị nri

※ Na-abawanye ikike nke mmepụta ahịrị ruo 50%

※ Melite ma mee ka ịdịmma ngwaahịa kwụsie ike-- Ọdịnaya mmiri ntinye nha nha na nke enwere ike ikwugharị

→ Belata ọnụ ahịa nrụpụta nke pellets PET: Ihe ruru 60% obere ike oriri karịa usoro ihicha nkịtị.

→ Mmalite ngwa ngwa na mechie ngwa ngwa --- Ọ dịghị mkpa tupu ikpo ọkụ

→ A ga-ahazi ihicha& kristal n'otu nzọụkwụ

→ Ejiri ahịrị igwe nwere sistemụ Siemens PLC nwere otu isi ọrụ ebe nchekwa

→ Na-ekpuchi mpaghara nke obere ihe owuwu dị mfe ma dị mfe iji rụọ ọrụ na nhazi

→ Ọnọdụ okpomọkụ nke onwe na oge ihicha setịpụrụ

→ Ọ dịghị nkewa nke ngwaahịa na dị iche iche nnukwu njupụta

→ Dị mfe dị ọcha ma gbanwee ihe

Igwe na-agba ọsọ na ụlọ ọrụ ndị ahịa

FAQ

Ajụjụ: Gịnị bụ mmiri ikpeazụ ị nwere ike nweta? Ị nwere oke ọ bụla na mmiri mbụ nke akụrụngwa?

A: Mmiri ikpeazụ anyị nwere ike nweta ≤30ppm (Were PET dị ka ihe atụ). Mmiri mbụ nwere ike ịbụ 6000-15000ppm.

Q: Anyị na-eji Ugboro abụọ yiri ịghasa extruding na agụụ degassing usoro maka PET extrusion granulating ahịrị, anyị ka ga-mkpa iji tupu Dryer?

A: Anyị na-atụ aro iji Pre-dryer tupu extrusion. Ọtụtụ mgbe, usoro dị otú ahụ nwere ihe achọrọ siri ike na mmiri mbụ nke ihe PET. Dị ka anyị maara PET bụ ụdị ihe nwere ike ịmịkọrọ mmiri sitere na ikuku nke ga-eme ka eriri extrusion na-arụ ọrụ nke ọma. Ya mere, anyị na-atụ aro ka iji pre-drier tupu gị extrusion usoro:

>> Na-egbochi mmebi hydrolytic nke viscosity

>>Gbochie ịba ụba ọkwa AA maka akụrụngwa nwere kọntaktị nri

>> Na-abawanye ikike nke mmepụta ahịrị ruo 50%

>>Mmalite ma mee ka ogo ngwaahịa ahụ kwụsie ike-- Ọdịnaya ntinye mmiri nha nha na nke enwere ike ikwugharị

Ajụjụ: Gịnị bụ oge nnyefe nke IRD gị?

A: 40 ụbọchị ọrụ kemgbe anyị nwetara nkwụnye ego gị na akaụntụ ụlọ ọrụ anyị.

Ajụjụ: Kedu maka ntinye nke IRD gị?

Injinia nwere ahụmahụ nwere ike inye aka ịwụnye sistemụ IRD maka gị na ụlọ ọrụ mmepụta ihe gị. Ma ọ bụ anyị nwere ike ịnye ọrụ nduzi n'ịntanetị. Igwe ahụ dum na-eji plọg ụgbọ elu, dị mfe maka njikọ.

Ajụjụ: Gịnị bụ IRD nwere ike itinye maka?

A: Ọ nwere ike ịbụ tupu nkụ maka

- PET/PLA/TPE Mpempe akwụkwọ extrusion igwe ahịrị

- PET Bale eriri eme igwe akara

- PET masterbatch crystallization na ihicha

- PETG Sheet extrusion ahịrị

- PET monofilament igwe, PET monofilament extrusion ahịrị, PET monofilament maka broom

- Igwe ihe nkiri PLA/PET

- PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS wdg.

- Thermal usoro makaiwepụ oligomeren izu ike na ihe ndị na-agbanwe agbanwe.