PLA PET thermoforming Sheet extrusion ahịrị

Infrared crystal dryer+ PET Sheet Extrusion line

Uru anyị na-eme

>>LIANDA na-emepụta iheSingle ịghasa extrusion ahịrị nwere infrared crystal dryermaka mpempe akwụkwọ PET, 20mins tupu ihicha na crystallization, mmiri ikpeazụ nwere ike ịbụ ≤50ppm (Akara igwe na-arụ ọrụ kwụsie ike, akwụkwọ mpempe akwụkwọ ikpeazụ kwụsiri ike)

The extrusion akara nwere àgwà nke obere ike oriri, mfe mmepụta usoro na mfe mmezi.

Usoro ịghasa nke nkewa nwere ike belata mfu viscosity nke resin PET, mpịakọta calender nke dị gịrịgịrị na nke dị mkpa na-eme ka mmetụta jụrụ oyi, ikike na ịdị mma mpempe akwụkwọ.

Multi-mpaghara dosing feeder na-achịkwa pasent nke ihe ọhụrụ, ihe eji emegharị ihe na nnukwu batch kpọmkwem,.

Ejirila mpempe akwụkwọ ahụ nke ọma maka ụlọ ọrụ nkwakọ ngwaahịa thermoforming.

>>Infrared kristal draya --Akọrọ &Crystallize R-PET flakes/chips na 20mins na 30ppm site na-azọpụta 45-50% ume ọnụ ahịa.

※Na-egbochi mmebi hydrolytic nke viscosity.

※ Gbochie ịbawanye ọkwa AA maka akụrụngwa nwere kọntaktị nri

※ Na-abawanye ikike nke mmepụta ahịrị ruo 50%

※ Melite ma mee ka ogo ngwaahịa ahụ kwụsie ike-- Ọdịnaya mmiri ntinye nha nha na nke enwere ike ikwugharị

Belata ụgwọ nrụpụta nke mpempe akwụkwọ PET: Ihe ruru 60% obere ike oriri karịa usoro ihicha nkịtị

Mmalite ngwa ngwa na mechie ngwa ngwa --- Ọ dịghị mkpa tupu ikpo ọkụ

A ga-ahazi ihicha & kristal n'otu nzọụkwụ

Iji melite ike tensile nke akwụkwọ PET, welie uru agbakwunyere--- Mmiri ikpeazụ nwere ike ịbụ ≤30ppm site na 20minsAkọrọ & kristal

- Ejiri ahịrị igwe nwere sistemụ Siemens PLC nwere otu isi ọrụ ebe nchekwa

- Na-ekpuchi mpaghara nke obere ihe owuwu dị mfe ma dị mfe iji rụọ ọrụ na nhazi

- Okpomọkụ nọọrọ onwe ya na oge ihicha edobere

- Enweghị nkewa nke ngwaahịa nwere nnukwu njupụta dị iche iche

- Ọ dị mfe ọcha ma gbanwee ihe

>> PET Extrusion igwe ahịrị

| Nlereanya | Multi oyi akwa | Otu oyi akwa | Na-arụ ọrụ nke ọma |

| Nkọwapụta Extruder | LD75&36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Ọkpụrụkpụ nke ngwaahịa | 0.15-1.5 mm | 0.15-1.5 mm | 0.15-1.5 mm |

| Isi moto ike | 110kw/45kw | 110kw | 250kw/55kw |

| Ike extrusion kacha | 500kg / h | 450kg / h | 800-1000kg / h |

Ndepụta igwe

| Ngwakọta igwe | ||

| NO | Igwe | Ọnụọgụ |

| 1 | PET Infrared crystal dryer | 1 set |

| 2 | Vacuum skru feeder | 1 set |

| 3 | Ugboro abụọ ịghasa extruder | 1 set |

| 4 | Vacuum sistemu nrụgide na-adịghị mma | 1 set |

| 5 | Nzacha ọwa ugboro abụọ | 1 set |

| 6 | Agbazekwa metering mgbapụta | 1 set |

| 7 | PET pụrụ iche ebu anwụ | 1 set |

| 8 | Atọ mpịakọta calendering na-akpụ akụkụ | 1 set |

| 9 | Ihe mkpuchi mmanụ silicone na ngwaọrụ oven | 1 set |

| 10 | Ihe eji egbutu ihe Edge | 1 set |

| 11 | Ngwa mgbake ihe Edge | 1 set |

| 12 | Sistemụ ikuku ikuku abụọ | 1 set |

| 13 | SiEMENS sistemu njikwa interface mmadụ-igwe | 1 set |

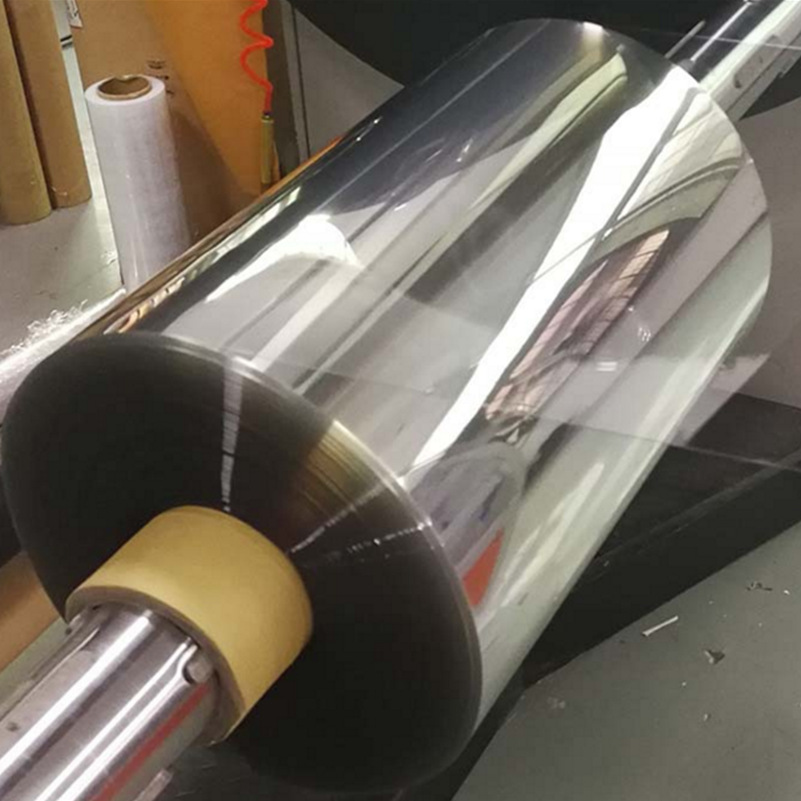

Foto igwe

FAQ

Ajụjụ: Gịnị bụ mmiri ikpeazụ ị nwere ike nweta?Ị nwere oke ọ bụla na mmiri mbụ nke akụrụngwa?

A: Mmiri ikpeazụ anyị nwere ike nweta ≤30ppm (Were PET dị ka ihe atụ).Mmiri mbụ nwere ike ịbụ 6000-15000ppm.

Q: Anyị na-eji Ugboro abụọ yiri ịghasa extruding na agụụ degassing usoro maka PET mpempe akwụkwọ extrusion, anyị ka ga-mkpa iji tupu Dryer?

A: Anyị na-atụ aro iji Pre-dryer tupu extrusion.Ọtụtụ mgbe, usoro dị otú ahụ nwere ihe achọrọ siri ike na mmiri mbụ nke ihe PET.Dị ka anyị maara PET bụ ụdị ihe nwere ike ịmịkọrọ mmiri sitere na ikuku nke ga-eme ka eriri extrusion na-arụ ọrụ nke ọma.Ya mere, anyị na-atụ aro ka iji pre-drier tupu gị extrusion usoro:

>> Na-egbochi mmebi hydrolytic nke viscosity

>>Gbochie ịbawanye ọkwa AA maka akụrụngwa nwere kọntaktị nri

>> Na-abawanye ikike nke mmepụta ahịrị ruo 50%

>>Mmalite ma mee ka ogo ngwaahịa ahụ kwụsie ike-- Ọdịnaya ntinye mmiri nha nha na nke enwere ike ikwugharị

Ajụjụ: Anyị ga-eji ihe ọhụrụ eme ihe ma anyị enweghị ahụmahụ ọ bụla maka ihicha ihe dị otú ahụ.Ị nwere ike inyere anyị aka?

A: Anyị factory nwere Test Center.N'ime ụlọ nyocha anyị, anyị nwere ike ịme nnwale na-aga n'ihu ma ọ bụ kwụsịchaa maka ihe nlele ndị ahịa.Ejiri akụrụngwa akpaaka zuru oke yana teknụzụ nha.

Anyị nwere ike igosi --- Nbufe/ebunye, ihicha& kristal, ichasa.

Ihicha na kristal nke ihe iji chọpụta mmiri fọdụrụnụ, oge obibi, ntinye ike na ihe onwunwe.

Anyị nwekwara ike igosipụta arụmọrụ site n'inweta nkwekọrịta maka obere batches.

Dị ka ihe onwunwe na mmepụta ihe chọrọ, anyị nwere ike ịdepụta atụmatụ gị.

Injinia nwere ahụmahụ ga-eme ule ahụ.A na-akpọ ndị ọrụ gị nke ọma ka ha sonye na ụzọ nkwonkwo anyị.N'ihi ya, ị nwere ma ekwe omume inye aka ifịk ifịk na ohere n'ezie ịhụ anyị ngwaahịa na-arụ ọrụ.

Ajụjụ: Gịnị bụ oge nnyefe nke IRD gị?

A: 40 ụbọchị ọrụ kemgbe anyị nwetara nkwụnye ego gị na akaụntụ ụlọ ọrụ anyị.

Ajụjụ: Kedu maka ntinye nke IRD gị?

Injinia nwere ahụmahụ nwere ike inye aka ịwụnye sistemụ IRD maka gị na ụlọ ọrụ mmepụta ihe gị.Ma ọ bụ anyị nwere ike ịnye ọrụ nduzi n'ịntanetị.Igwe ahụ dum na-eji plọg ụgbọ elu, dị mfe maka njikọ.

Ajụjụ: Gịnị bụ IRD nwere ike itinye maka?

A: Ọ nwere ike ịbụ tupu nkụ maka

PET/PLA/TPE Mpempe akwụkwọ extrusion igwe ahịrị

PET Bale eriri eme igwe akara

PET masterbatch crystallization na ihicha

PETG Sheet extrusion ahịrị

PET monofilament igwe, PET monofilament extrusion ahịrị, PET monofilament maka broom

Igwe ihe nkiri PLA/PET

PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS wdg.

Thermal usoro makaiwepụ oligomeren izu ike na ihe ndị na-agbanwe agbanwe.